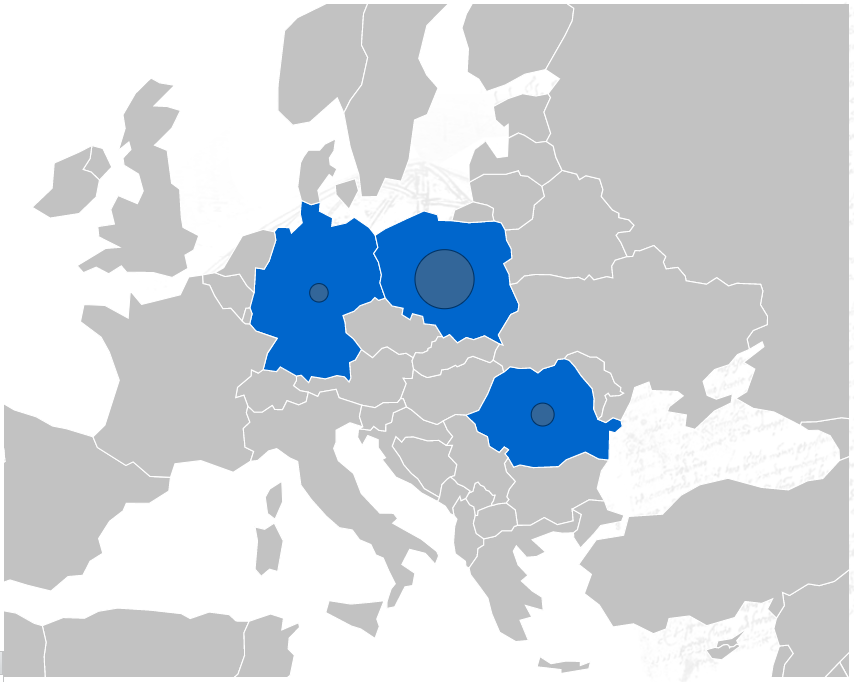

HEET II project is being carried out by a consortium of seven partners from three different countries with running coal mining industries constitutes excellent balance between the theoretical and innovative content and the practical aspects of the work as well as pan-European dimension of the project. The consortium includes a participation of industry, research institutions and universities, thus allowing research, models build, laboratory and mine tests as well as increasing success of implementation.

Instytut Techniki Górniczej KOMAG (KOM)

Komag institute is state owned research and development centre of organizational and proprietary structure adapted to the market activity in the European Research Area and of the organizational culture creating a friendly climate for generating new ideas and realizing the innovative activities, i.e. transforming new ideas into new products.

The KOMAG activity incorporates scientific and research projects on improvement of mining technology, haulage and processing of minerals. The projects are oriented onto anthropotechnical systems in the aspect of reliability, work safety and comfort.

The Division of Mechatronic Systems employs an interdisciplinary team of specialists, who can realize complicated mechatronic and electro technical projects, which combine electrics, mechanics, automation, computer science and electronics, taking advantage of the synergy effect.

The range of scientific, research and technical projects, realized by the Division of Mechatronic Systems, is as follows:

- designing and integration of automation systems, monitoring and industrial sensor technologies based on different hardware platforms,

- designing and construction of mechatronic and electro technical systems,

- designing and construction of battery power supply for mobile machines,

- designing and construction of drives and control systems,

- designing and construction of mine electrical network,

- modelling and simulation of mechatronic and electro technical systems,

- designing of systems for visualization of technological processes in various environments,

- a development of customer and server applications,

- a creation of applications, websites and internet services,

- designing and implementation of microprocessor electronic systems,

- multi diagnostic of machines and equipment based on several technologies.

An integration with the European Research Area as regards designing, testing and manufacture of machines as well as an increase in competiveness of Polish solutions in the European market is the main objective of the activities undertaken by KOMAG within the basic and strategic tasks.

A close collaboration with foreign partners, representing the leading institutes in Europe, plays an essential role. During last 15 years KOMAG was participating in 23 European projects within such programmes as: V. and VI and VII. Framework Programmes, Research Fund of Coal and Steel, COST 356, Leonardo, ERASMUS +. At the moment KOMAG is coordinating three international projects of a total budget over 3 500 000 euro

Sun, Wind, … Energy (SWE)

The company disposes production facility in Wodzisław-Śląski (Poland) at Marklowicka Street, which enables the production and quality tests of composite structures. Faicility consists of:

- 3 production halls with a total area of 3900 m2.

- Storage and storage yards with an area of 740 m2.

- Laminate production facility: a fully equipped laminate division, including molds for laminates, gelcoilers, devices for resin, extracts and ventilation system, social facilities for employees, etc., facilities sufficient for the current production of laminates and the implementation of activities planned in the project.

- Equipment for mechanical treatment: equipment for machining of laminate elements, machines for trimming, prefabrication, drilling, surface treatment, equipment assembly, mechanical prefabrication, assembly of accessories, etc. The facilities are sufficient for the ongoing production of laminates and the implementation of activities planned in the project.

- Laboratory for conducting R & D and quality researches.

Research apparatus:

SWE will also have the research equipment necessary to carry out the tests, i.e. special measuring equipment allowing to determine the parameters of samples and composite products: pull-out, pull-off, Schmidt hammer, penetrometer, endoscopic camera, drill, endurance machine, low-temperature chamber

(40oC), a stand for testing on a natural scale in predetermined conditions, technological and research equipment for the evaluation of materials used, especially composite materials, and for the production of samples and prototypes of finished products with vacuum and vibration forming.

SWE is currently carrying out a commercial contract for „Development, production and testing of a prop made of composite materials intended for use in underground mines with a minimum load capacity of 200 kN within the range of 0.8 to 1.5 m”. The value of works covered by the agreement amounts to PLN 473,739.42 including VAT, and the implementation period until 30.06.2020. The project covers the following areas:

- Development of the prop structure (prop concept, analysis of materials and performance of samples, numerical modelling of the behavior of composite materials, performance of the form and prototype).

- Tests and laboratory tests of the props (by the end of 05/2019, strength tests of the prop prototype and the development of a series of types of props were carried out). Within the framework of tests and laboratory tests in 2019, tests and analyses of the series and the summary of laboratory tests will be carried out.

- In 2020, the props will be tested and subjected to underground tests.

The contract is implemented according to the schedule and the financial advancement as of 30.05.2019 is about 80%. The effects achieved at the stage of strength tests exceeded the initial requirements for props by the customer, which proves the significant knowledge and competence of SWE sp. z o.o. in the field of composite technology and its implementation in new, innovative applications in the mining industry.

JSW Innowacje SA (JSWI)

JSW Innowacje S.A. with its registered office in Katowice was established on 31 January 1996 (the Company’s original business name was Polski Koks S.A.). Initially, the Company’s core line of business was wholesale of fuel and derivative products. In May 2017, Polski Koks S.A. changed its name to JSW Innowacje S.A. Together with the change of the name, the Company’s core business also had changed.

JSW Innowacje S.A. provides research and development support for the entire JSW Group. The Company’s activity covers all phases of R&D activity of the JSW Group, including feasibility studies and supervision of projects executions and implementations. JSW Innowacje’s strategy postulates: expanding the R&D activity, including development of technologies and systems, and increasing the potential and possibilities of the Polish mining industry.

JSW Innowacje S.A. uses its geographical location to engage JSW’s research and development communities in the area of Upper Silesia and the center of Kraków to stimulate the development of the entire Capital Group. The company’s vision is to obtain the status of a leading innovation center for the mining industry on the European market. The company’s mission is to develop technologies and systems that increase the potential and capabilities of the Polish mining industry. The main goal is to achieve a significant position in the supply of advanced technologies and services for mining.

Główny Instytut Górnictwa (GIG)

The Central Mining Institute is a scientific and developmental organization, under the authority of the Ministry of Energy, working not only for the benefit of the mining industry, but also for enterprises representing different branches. GIG is engaged in problems of mining engineering, safety in mines and environmental protection. The activities of the Institute comprise the following fields: new technologies in mining, geology and hydrogeology, geophysical engineering, natural and technical hazards in the mining industry, monitoring and environmental protection in areas of mining exploitation, the certification of equipment and materials. Furthermore the Institute possesses an underground testing facility which is unique in Europe and located in the Experimental Mine “Barbara”. GIG has extensive experience in participation as a partner and co-ordinator of applied research projects, such as RFCS projects e.g. GASdrain, EXPRO, HUGE and ongoing e. g. MapRoc, HYDROCoal and Framework projects. GIG develops network collaboration regarding sustainable mining and the conversion of post-mining into areas of socio-economic benefits. Therefore a number of initiatives and solutions taken from projects results have already been implemented. Specialists of Underground Research Department and Department of Explosion-Proof Protection and Conformity Assessment Department “JOZ”, the Explosion-Proof Protection Safety Team will be involved in the HEET II project. “JOZ-P” conducts complex activities in the field of evaluation of products intended for use in potentially explosive atmospheres. Within the Conformity Assessment Department there is a Certification Team. The Product Certification Team conducts activities based on the requirements of the “ATEX” Directive and the International Electrotechnical Commission IECEx. GIG is Notified Body I ATEX area, number 1453. An important element of the assessment is the research conducted by the Laboratory of Explosion-Proof Systems and Protection and Explosimetry “JOZ-P.1” (PCA accreditation number AB1710) which operates within the structure of the Department. The Laboratory is accredited by the Polish Centre for Accreditation in the scope of research covered in the harmonised standards for the “ATEX” Directive. The representatives of above departments participate in international scientific-technical conferences designed for mining problems, the activities of Safety and Post-mining accidents’ Commissions constituted by the President of the State Mining Authority as well as International Conferences on Safety in Mines Research Institutes. Bearing in mind more than 70 years experience in the above domains Central Mining Institute has extended knowledge of the work needed to complete this project.

Politechnika Śląska (SUT)

The Silesian University of Technology (SUT) is the institution of higher education and scientific research, one of the biggest technical universities Poland. It was established in 1945 as a scientific and educational facility for Upper Silesia, the most industrialized area in Poland, and one of the most industrialized in Europe. For over 70 years of its history, it has always been a public institution, playing a cultural and opinion forming role in the region. The University consists of 15 faculties, located in three towns of Silesia region. The Silesian University of Technology occupy leading positions in both national and international rankings. It ranked 5th among technical universities and 13th among all universities in Poland in the “Perspektywy” Educational Foundation Ranking. In the SCImago Institutions Ranking (SIR), an international classification of higher education institutions, Silesian University of Technology was awarded the 4th place in Poland and 17th in Eastern Europe. According to the report made by Sedlak & Sedlak company, 1 in 12 chairmen in Poland graduated from SUT. SUT was also awarded an ELSEVIER Research Impact Leaders 2016 award in the Engineering and Technology category, focusing on the impact of the university on the visibility of Polish science worldwide.

The Faculty of Electrical Engineering was one of the first founded faculties of the University. At present the Faculty employs about 30 professors and associate professors and 85 doctors. Council of the Faculty of Electrical Engineering has the right to confer doctoral degrees in the disciplines of electrical engineering and electronics and telecommunications, as well as a D.Sc. degree in technical sciences in the discipline of electrical engineering. The scope of research conducted at the Faculty of Electrical Engineering is closely correlated with the needs of industry. The Faculty leads research collaboration with dozens of universities located in all continents, as well as with Polish and foreign industry companies. The Faculty has a modern research and teaching infrastructure, which consists of more than 60 specialized laboratories, multimedia lecture halls and classrooms as well as seminar rooms.

Department of Power Electronics, Electrical Drives and Robotics, which is one of six departments in the structure of the Faculty of Electrical Engineering, undertakes basic and applied research that is built into world’s RTD (Research and Technological Development) system. RTD projects are undertaken in cooperation with Polish, European and World universities, research centers and industry. The strong, flexible RTD and teaching potential allowing undertaking new challenging projects has been built in the Department. The Department undertakes RTD projects in the field of power electronics, power conversion, industrial electronics, power electronic drives, EMC, superconductivity applications, electrotechnology, electroheat and mobile robots. The Power Conversion Group counts at the moment 12 persons – 8 permanent staff and 4 PhD students. Scientists have in disposal three laboratories: Laboratory of Power Electronics, Laboratory of High Frequency Conversion and Laboratory of Superconductivity equipped with relevant equipment (including power sources and professional measuring equipment) and other labs of the Department. The project will fully utilize above mentioned resources.

The Institute for Advanced Mining Technologies (AMT)

RWTH Aachen University (RWTH) has for many years been ranked as the top technical University of Excellence in Germany. Joint research with industry and large collaborative research centres are particular strength of this partner.

The Institute for Advanced Mining Technologies (AMT), is part of the Division of Mineral Resources and Raw Materials Engineerin at the RWTH Aachen University. The research activities of AMT are subdivided into different areas of application; Sensor Technology and Automation, Diagnostics and Maintenance and the Rock-cutting group. The AMT employs around 40 people, which are involved in research and development. Among them are about 20 PhD students. Their background is a diverse as the areas of application, which are conducted at AMT. Especially the expertise in the area of Sensor Technology and automation will be of great benefit for the proposed project. This also includes increasing competence in the field of digitization in mining. The research focus in recent years has been the utilization, processing and transmission of a wide variety of data forms, such as position data, sensor data and comparable. This topic also includes the evaluation and interpretation of the collected data. Furthermore, a lot of project experience, which was gained at several state and EU funded projects, will be incorporated into this project.

„Dunărea de Jos” University of Galaţi (UGAL) is a state-owned higher education institution. Its present enrollment of about 15 000 students places it as a medium-size university in the South East of România. The Dunărea de Jos” University of Galaţi is the most important institution of higher education in the South – Eastern part of Romania, being the centre of technical, scientific, cultural and social progress with immediate or medium to long term applicability, meant primarily to contribute to the progress of Galaţi.

„Dunarea de Jos” University of Galati has been nationally and internationally acknowledged during its 70 years of existence. „Dunărea de Jos” University of Galati encompasses 15 faculties, 49 departments, 3 doctoral schools and offers numerous academic programs that overarch all levels of university training: 65 bachelor degree programs, 48 Master programs, 11 open and distance learning academic programs, 12 PhD degree programs, many high-level postgraduate study programs, and programs for professional reconversion and training. All programs included in the educational offer are either accredited or authorized. The degrees granted by „Dunarea de Jos” University of Galati are recognized in almost all countries.”Dunarea de Jos” University of Galati is one of the most important research centers in Romania. Over 20 accredited centres develop research activity and collaborate with similar Romanian or foreign research centres.

Automation and Electrical Engineering Department have major concern to develop a sustainable energy system. In this context, the Department of Automation and Electrical Engineering manages, master’s program the Efficient Energy Use and Renewable Energy Sources. Facilities for the Master’s programme were made in particular, by research projects. During 2006-2008 the members of the departments was a partner in the national project entitled Research on Interconnection assemblies wind power conversion system in order to Increase Energy Efficiency for a specific application. Substantial scientific contribution was made in the activities that were carried out a comparative study on alternatives for achieving wind systems for different applications: the consumer unique, network with national network and a study on power quality requirements of wind system National project, has researched (2007-2010) a Cogeneration system with fuel cell and thermal station without connection to the grid, and had the goal modelling, experimenting on the model, determining the characteristics of the system, as well as optimising the processes of multiple energy conversion. In the same period, has researched Power quality evaluation methods for energy efficiency increase in electrical systems with renewable sources.

The international project (financed by EEA Grants http://eeagrants.org/projectportal/ project_04-09/RO0054) with title „Integrated micro CCHP – Stirling Engine based on renewable energy sources for the isolated residential consumers from South-East region of Romania (m-CCHP-SE)” (project site www.mcchp.ugal.ro ) and had the scope to develop a trigeneration system for simultaneous production of power, heat and cold type off-grid. The specific objective of this project was to study, model, simulate, design and manufacture the mCCHP-SE system experimental model and to implement it in the experimental residential house located within the area of the Dunarea de Jos University campus (South-Eastern region of Romania).The aim of this project was to design and build an experimental model of a trigeneration as an alternative solution for obtaining electricity, heat and cold using traditional resources (wood), renewable energy (biomass, biogas) and solar energy system and that will serve as an experimental unit to investigate the potential of trigeneration systems for energy production and conservation.

There are three research centers in the Faculty of Automation, Computers, electrical and Electronics Engineering. Prof. Marian Gaiceanu is Director of Integrated Energy Conversion and Control of Advanced Complex Process Research Center since 2016